You have seen many new items coming into the market every day. The greater part of them are getting fruitful and creating colossal income. You have a thought as well. You should believe that you just gave this plan to a maker, he will deliver your item and presto! You will be effective as well. However, it’s a remarkable inverse. The fruitful excursion from a model plan to delivering an end result comprises of numerous intricate advances.

Fast prototyping organizations like Quick Immediate, who can help you from prototyping to on-request assembling to make your fantasy a reality. These organizations will make working plans out of your computer aided design configuration, make a genuine model, field test it, further develop it, lastly produce an end result out of it in brief days and to make your item more cutthroat on the lookout.

You can see the flowchart beneath to find out about the number of steps you would experience in the excursion from a plan to prototyping to the creation of the eventual outcome.

1) How to Change over Your Thought into A Genuine Item

As you can find in the diagram above, it isn’t so easy to change over your thought into an effective item. There are numerous stages, and it can require a very long time from the prototyping stage to the creation stage. The fundamental stages are given beneath, and I will examine every one of them exhaustively;

Planning

Prototyping

Limited scope Creation

Agreement Marking

Full-Scale Creation

Quality Testing, Pressing, and Shipment

2) How to make a practical Plan

You may have a harsh thought regarding the item in the mind, yet you need to make a useful plan on some product or if nothing else on a napkin with the goal that you can show it to your maker. On the off chance that you don’t have a clue how to utilize planning programming, don’t stress since that isn’t your responsibility to take care of. Your producer has numerous gifted originators; you need to tell your item construction and capacities in complete detail. They will make numerous plans dependent on your item appearance and usefulness until you are fulfilled. On the off chance that you need to make a plan at your home, you can, however it will defer the creation time, and your hand crafted plans actually need to finish a few assessments by proficient planners. In this way, it is ideal to set up contact with the best producer to set aside time and cash.

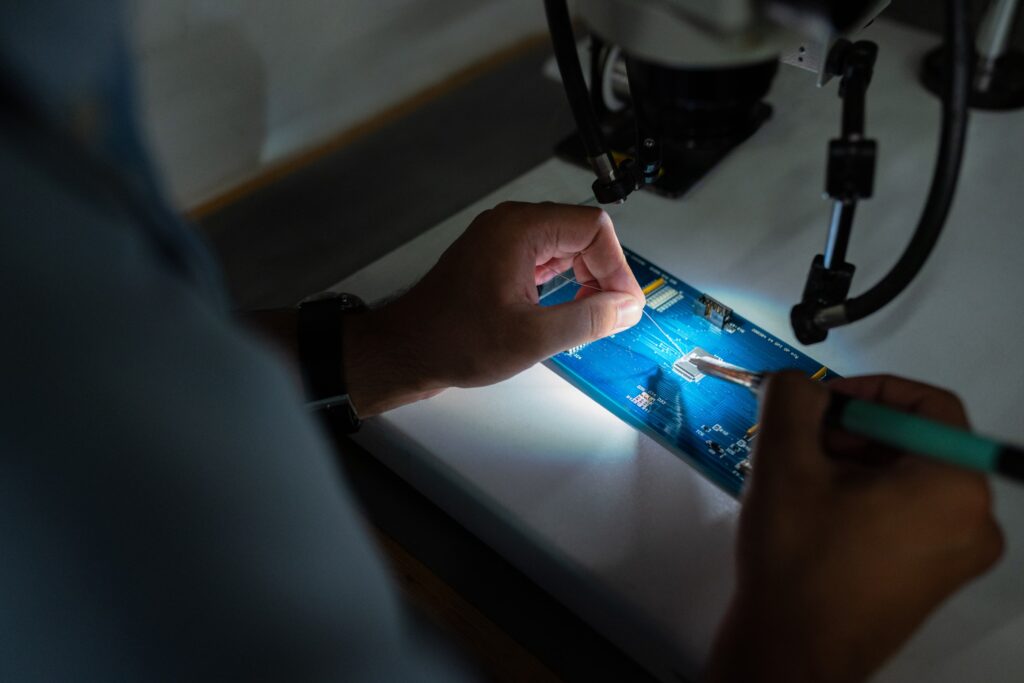

3) How to Fast Model your Plan

Presently, Since your last plan is prepared, the time has come to continue ahead to the following stage, which is prototyping. This stage is extremely imperative for your task. This stage chooses the quality, speculation, disappointment or achievement, and in general term of the task. Thus, it is prescribed to get into contact with the best proficient maker. Track down an expert maker who gives quick prototyping administrations to make a utilitarian model in less term to save both of your speculations and time.

The fundamental strategies that you can use to quick model your item are;

CNC Machining

Vacuum Projecting

Infusion Embellishment

Sheet Metal Creation

CNC machining: CNC machining is a subtractive cycle where a strong piece of crude material is cut into an ideal 3D mathematical shape and size. CNC machining is an exceptionally exact cycle to make various variations of beginning models. CNC machining might be somewhat exorbitant, yet it is beneficial as it’s accuracy work.

Vacuum Projecting: You can utilize this cycle to choose your last model from starting models. You can utilize this cycle to make your models close to end result quality and afterward field test them up to 100/pieces each day. This cycle is less expensive than CNC machining after you settle on starting models.

Infusion Trim: After you settle on the last model, you can test it on a limited scale of up to 200 to 500 pieces. You can utilize low-volume infusion forming machines to arrive at eminent model quality at a low cost. This interaction is a last model testing stage to check the public reaction to your item.

Sheet Metal Creation: On the off chance that your task has generally metal parts, your producer will utilize the sheet metal manufacture cycle to cut, twist, gather, weld, and clean your last metal item. Sheet metal creation is a quick, fast prototyping and eventual outcome fabricating technique. This cycle is utilized uniquely toward the finish to check public reactions about the last model.

You can likewise utilize infusion embellishment and sheet metal creation measures subsequent to prototyping to make items at an enormous scope.

4) How to put Last Model on the Creation Stage

Presently, your last model is prepared. You think your excursion is finished, yet no, you are just part of the way through.

RFQ: You need to contact numerous producers and get a RFQ, otherwise called ” Solicitation for Statement,” against your last model. The producer will look at your model and give you a wardrobe thought regarding the end result cost.

BOM: When you get a RFQ and settle on a particular maker, you need to examine further insights regarding the venture. For instance;

The end nature of your item

Segments of your item

Crude materials which will use in your venture

Cycles that will fabricate your item

This methodology is otherwise called the BOM ” Bill of materials,” which incorporates all the end result data.

Assembling Financial plan: Financial plan consistently is a key factor we need to consider. Remembering your financial plan, you should make a harmony between item quality and item cost. Then, at that point the maker will pick crude materials, machines, and different subtleties as per your necessities.

Trail Request: Prior to running your last model creation on full-scale, you should initially arrange some item pieces from the maker to check the eventual outcome quality and guarantee he is giving what he is promising.

Venture Cutoff time: To wrap things up, set a sensible cutoff time for your task. Thus, your agreement maker can convey your request on your assigned cutoff time without lessening the item quality.

Quality Confirmation: You need to sign quality affirmation testaments with your maker to guarantee the greatest of your items.

Shipment: When you are gone through all creation, investigation, and pressing issue, the last part is shipment. Due to the Covid, presently the delivery ability is Deficient. So we should watch out for coordinations.

Outline:

As you have seen above, fabricating an item from a harsh thought is anything but a simple cycle. There could be numerous components that will postpone the creation of the item, for example, your plan might be defective, models may not breeze through standard assessments, or your eventual outcome may not get a decent open reaction, and you should make changes or overhaul from the beginning. It could require months, even a long time, before you dispatch your item into the market. To keep away from superfluous tedious, it is crucial for contact a decent producer from the very beginning.

A decent producer will assist you with succeeding item improvement, assembling and save your ventures. The advantages of the great maker are given beneath;

Giving one-prevent administrations from prototyping to assembling to accelerate the plans and models of your item.

Assisting you with picking the best machining strategies as per your financial plan to guarantee low creation cost and great finished result quality.

Offering proficient designing help and transportation support.